HP 5000

High & Low Pressure Ducting

HP 5000 has an extensive range of twin and single wall components with 25mm and 50mm cavity insulation, giving it the versatility required to meet the widest range of applications. It can be used internally and externally.

The multifunctional overpressure exhaust system HP 5000 made of stainless steel is the perfect solution when it comes to over- and/or under pressures of up to 5000 Pascal and high or low exhaust gas temperatures.

The individual system components are available in single-walled or double-walled construction. The system offers maximum stability and easy installation with push-fit connections – resistant to vibrations of any kind.

- Available in 15 different diameters (from 130 mm to 700 mm)

- The flue gas leading inner liner is made from material 1.4404 in 1.0 mm wall-thickness

- 25 mm special insulation (50 mm and 100 mm available upon request)

- Stainless steel outer case is made from material 1.4031, is shiny and has a wall-thickness of 0,6 mm

- The exhaust system HP 5000 is certified according to European standards EN 1856

Features

An engineered multi purpose prefabricated ducting system suitable for high or low temperatures and fire rated applications.

HP 5000 is a lightweight twin wall insulated and single wall duct system specifically designed to handle both pressure and non-pressurised applications. As outlined in the product’s CE designation, the system is designed to operate under pressure up to 5000Pa (European Standard Designation H1) and with continuous operating flue gas temperatures up to 600°C (European Standard Designation T600).

The system is tested for Thermal Shock at 1000°C.

- Pressure tight up to 5000 Pa through premounted pressure-retaining locking bands

- Moisture-proof

- Suitable for dry and wet operation

- Continuous operating flue gas temperatures up to 600 °C in continuous operation, tested for thermal shock at 1000 °C

- Suitable for all fuels

- For industrial applications as an exhaust system for emergency power generators, thermal power stations and boilers. Suitable as a kitchen exhaust system as well as a protection for supply lines or as a mechanical smoke extraction system.

- Easy assembly of the inner liner due to flange and v-shaped clamping band

- Adapter incl. counterflange for customer flanges available upon request

- No welding work required on site

- Stainless steel inner liner with combined flange connector, element height 307-960 mm

- 0.6 mm inner liner made of stainless steel 1.4404 for diameter from 130-350 mm; 1 mm inner liner for all diameters

- 0.6 mm outer liner of stainless steel 1.4301 for diameter from 130-550 mm; 0.7 mm outer case for diameters starting from 600 mm

- Mineral wool insulation

Technical Specification

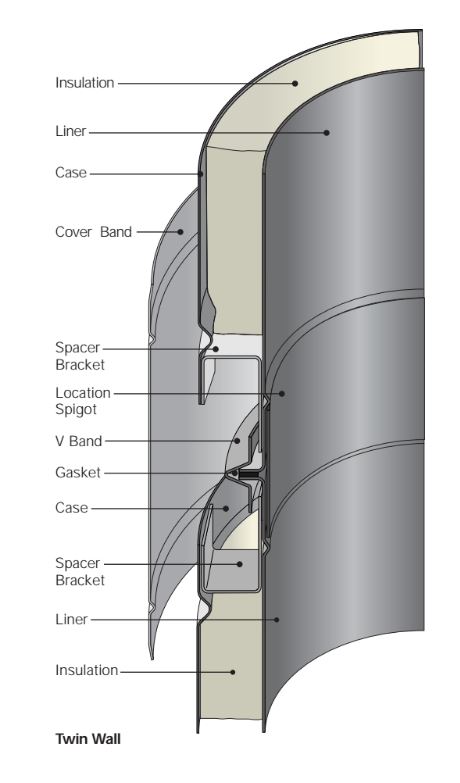

The Twin Wall System consists of:

- Inner Liner 316L Stainless Steel; seam welded continuous construction with an engineered flange at each end. Available in 0.6mm and 1mm inner liner thickness. 25mm or 50mm cavity filled with a mineral fibre insulating blanket.

- Internal Diameters: 130 – 800mm.

- The 0.6mm option is available for diameters from 130 – 350mm..

(25mm and 50mm air cavity versions are available on request). - Outer casing 304 stainless steel; 0.6mm for 130 to 550mm diameters and 0.7mm for 600 to 800mm diameters.

- The specially designed joint between the components creates a pressure resistant and structural liner.

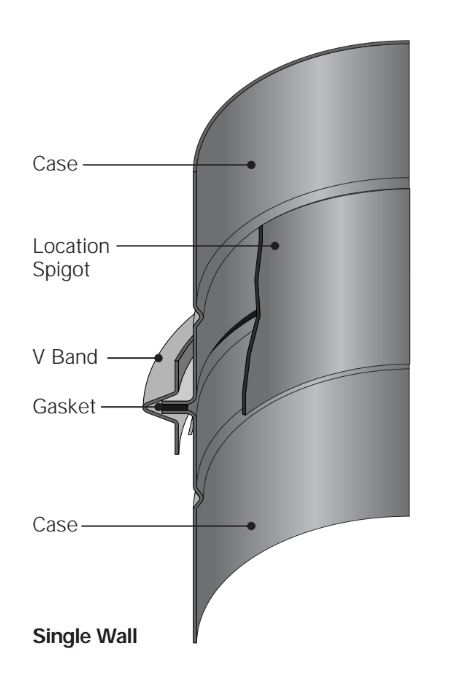

The Single Wall System consists of:

- 316L Stainless Steel; seam welded continuous construction with an engineered flange at each end. Available in 0.6mm and 1mm.

- Internal Diameters: 130 – 800mm.

- The 0.6mm option is available for diameters from 130 – 350mm.

- The specially designed joint between the components creates a pressure resistant and structural liner.

- No sealants are required as the joints come with a pre-installed gasket.

Forming the joint

The components are flanged at both ends with a spigot at the male end. The spigot protrudes by 25mm to ensure correct alignment of the joint and seating of the gasket on the engineered flanges.

A gasket is pre-installed on the male end of the component for ease of installation.

When two components are butted together the joint is secured using a V Band.

No sealants are required as the joints come with a pre-installed gasket.

Expansion Allowance

As the method of assembly for HP 5000 provides a continuous structural inner wall, normal expansion of the duct in its entirety must be allowed for by the use of expansion components.

Performance

Working pressure:

With Expansion Lengths up to 40Pa

With Expansion Bellows up to 5000Pa

Maximum Temperature Rating: continuous 600°C (European Standard Designation T600).

HP 5000 is available in a range of 18 internal diameters from 130mm to 800mm. The flange to flange installed straight lengths are 307, 470 and 960mm long. The external diameter is dependent on the width of the cavity – 25mm or 50mm. Specialised components can be manufactured to suit application requirements.

Supports

HP 5000 must be supported using only Schiedel Rite-Vent approved components, in conjunction with suitable steel work as necessary. Care is needed to ensure that supports are capable of accommodating expansion.

Applications

A typical range of applications would include:

- Diesel generators and turbines

- Boilers (high or low temperature)

- Smoke and waste extraction

- Refuse and laundry chutes

- Lightweight particle movement

- Kitchen extraction & Kitchen exhaust air

- Thermal power stations

- Petrol powered generators

- Emergency generators

- Smoke and waste gas extraction

- Refuse and laundry chutes

- Transportation shaft

- Forging furnaces

Showing the single result